Al Rostamani Technologies of the UAE last year started manufacturing a range of "Frater" products, a brand traditionally associated with lighting control gear, originating in Spain. The brand has established itself in the European and American market since early 1970s. It has recently been relaunched in Europe and the Middle East, offering commercial and industrial luminaries as well as lighting control gear, including the full range of ballasts, ignitors and capacitors.

Frater products emanate from the main facilities located in Barcelona, Spain.

Al Rostamani Technologies, as an associate company, is involved in engineering and manufacture of luminaries, lighting control gear and accessories and markets the brand in Asia, Africa and the Middle East from its Dubai offices.

A 42,000 sq ft purpose-built factory is now under construction in the Al Quoz area of Dubai, which will house the multi-million-dollar plant and equipment for fully-automated computer-controlled production lines to manufacture Frater ballasts and batten fittings.

"The Frater brand is aimed at the quality-conscious user, who demands value. Our goal is to provide innovative products that excite our customers and exceed their expectations of quality features and enduring values, " says Suresh Jacob, general manager at Al Rostamani Technologies.

"We strive to apply the latest technologies in our design, development, production and quality control departments so as to offer a product of consistent quality that offers value for money," he explains.

"We operate our business to provide an excellent return to our shareholders. And this is achieved by working in an open partnership with our employees, dealers and suppliers as we serve our customers in the electrical and construction industry," he continues.

The range of lighting fixtures manufactured and distributed under the Frater brand, include batten luminaires for fluorescent lighting, industrial fluorescent luminaires, weatherproof anti-corrosive fluorescent luminaries, modular recessed fluorescent luminaires as well as downlights.

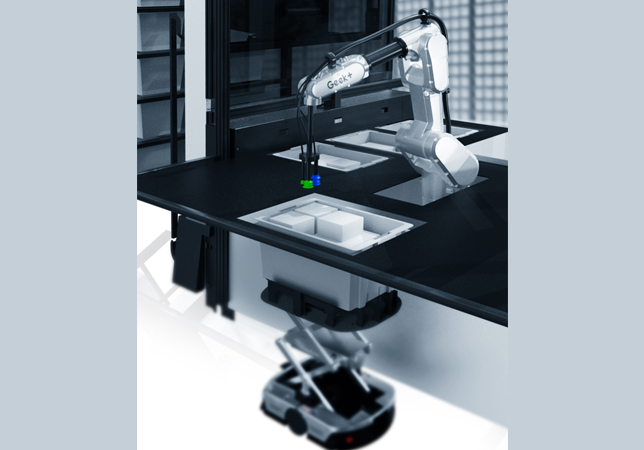

"In addition to luminaires, we also manufacture the heart of fluorescent lighting - the ballast," he says. "Frater ballasts, based on European design and technology, are manufactured on fully-automated, computer-controlled production and assembly lines to eliminate the human error factor and assure consistent quality and reliability."

Jacob points out that the Frater ballast, which is largely targeted at the European market, has an energy-efficient design.

"Being manufactured from electrical grade steel selected for its well-defined watt loss properties and polysterimide insulated high-grade copper, the ballasts have very low energy losses. Maximum service life and minimum temperature rise is guaranteed by the choice of insulating materials, and vacuum impregnation process. Reliability and quality is ensured by carefully selected raw materials, using a high-precision fully automated manufacturing process and 100 per cent on-line automatic testing at each stage of the production and assembly process.

"In-house production of ballast assures the customer of exceptional performance of the light fitting," Jacob points out. "An inefficient ballast results in high losses, which in turn leads to high operating temperatures. Energy losses not only increase electricity bills, but also reduce the life of the lamp, control gear components and ballasts due to the higher operating temperature. Also, the air-conditioning costs substantially increase due to the additional heat load.

Jacob says that due to lack of regulations in the Middle East, the use of cheap and inefficient ballasts is rampant. "These result in utter waste of electrical energy, which is generated from scare resources. Hopefully authorities in the Middle East will soon wake up and follow the examples of the West and bring in regulations which will curb the use of inefficient ballasts.

"Frater products, in general, use a choice of raw materials from carefully-developed vendors of quality products. For example, properly treated galvanised sheet steel is generally used with polyester paint finishes; gloss levels are carefully controlled to ensure that the product meets the specifications; louvered diffusers are the best quality available from well-known European manufacturers; and acrylic diffusers and other plastic-based parts meet stated specifications, manufactured in ISO 9001-certified production facilities.

"Components and control gear used in Frater light fittings are the best available in their class from European suppliers meeting international quality requirements. Energy-efficient Frater ballasts are designed and manufactured specifically for the particular lamp and fitting. All fittings are fully tested to ensure that the customer gets a properly checked quality product.

Frater products are sold and serviced through dealers and wholesalers in each country on the company's global network. Technical support and marketing assistance is provided from its Dubai office for the Middle East, Asia, Africa and CIS countries. The Barcelona office supports the territories of Europe and South America.

.jpg)

.jpg)

.jpg)