Saudi Lighting Company (SLC), which has contributed to many prestigious projects, added one more laurel to its record when it successfully closed a big deal supplying lighting fixtures at Kingdom Centre.

The company was involved in the Kingdom Centre at the design stage, and after many studies of lighting options and calculations for the ideal lighting concept lasting three years, the suitable luminaries were installed in the project.

SLC has supplied different lighting fixtures such as Commercial Lighting and Exit/Emergency Signs as well as a special down-light concept which has been designed and developed to be installed in the sculpture portion of the tower.

"Research and development, lighting design and manufacturing departments always work as one team to find the right solution for any project," says Saudi Lighting marketing support manager Bandar Al Toaimi.

The company is currently working on the Sabic headquarters building in Riyadh, the King Fahd Specialist Hospital in Dhahran and the General Presidency of Girls Education Schools.

Moreover, SLC has been involved with most recent projects such as Al Faisaliah Tower, King Fahd International Airport and NCCI headquarters. Saudi Lighting also worked on Kingdom Holding's hospital and school projects.

"We are not just planning for 2002, we have an eye on the future. Our strategies are to concentrate on increasing market share, meet customer requirements by providing different lighting application solutions, and achieving the company policy toward Saudisation in all departments," says Al Toaimi.

synopsis

Outling some of the major aspects of the company, Al Toaimi says: ''SLC expanded and developed its products and manufacturing processes according to economic developments and marketing response.

''In 1978, SLC started production of outdoor lighting fixtures in participation with Asia Swedish Company. In 1989, the company merged with Arabian Lighting Company in manufacturing indoor lighting fixtures. It has become a leading manufacturer of lighting fixtures in the Middle East solving a lot of customers' demands.

assets

''The main factors in the success of SLC in the lighting field are: Competent management, engineering development and creativity of design, skilled labour and the direct effect of sales representatives.

''The company ensures that all its employees participate in the success of the company to be the leader in its industrial field as the biggest producer of lighting in Saudi Arabia with a production capacity of more than 2.8 million-unit annually.

products

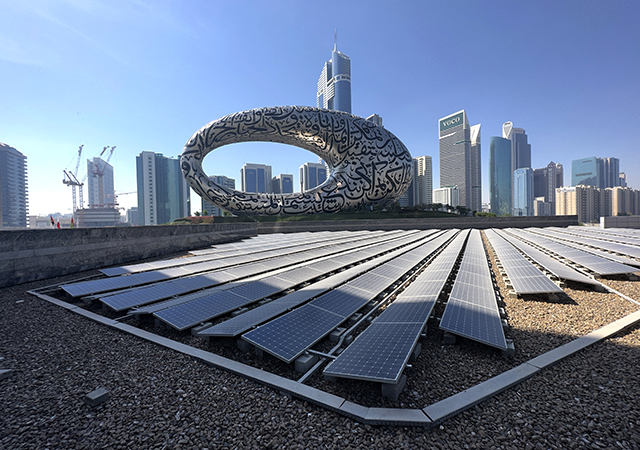

''With a comprehensive production range, we service indoor and outdoor lighting appliances: Residential, commercial, industrial. Moreover, we are pioneers in energy conservation products and cost-effective installation and operations.

QMS

''The main target of a Quality Management System (QMS) is the full customer satisfaction and safety by systematising the manufacturing of products according to SASO and IEC standards. The company's achievement of ISO 9001 quality system standard accredited by the British Standard Institution and SASO quality mark insures that all production lines work to national/international standards.

hi-tech systems

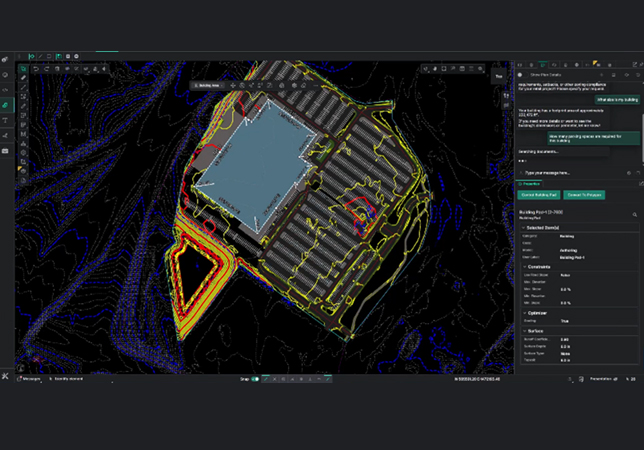

''The company realised that success cannot be achieved unless technology was used for both productive and administration processes. Therefore, all the departments of SLC were connected with internal network using Oracle Applications, which the company depends on in all productive and administration processes. SLC has become the first Saudi Company applying this system comprehensively in all its productive and administration operations. Furthermore, the company uses CAD programs for designing and developing products according to customer and R&D specifications.

''Input and output systems and programs provided the company with the capability to supervise and follow-up and guarantee data reliability. Accordingly, all accurate information in technical support and planning sections are supportive to manufacturing.

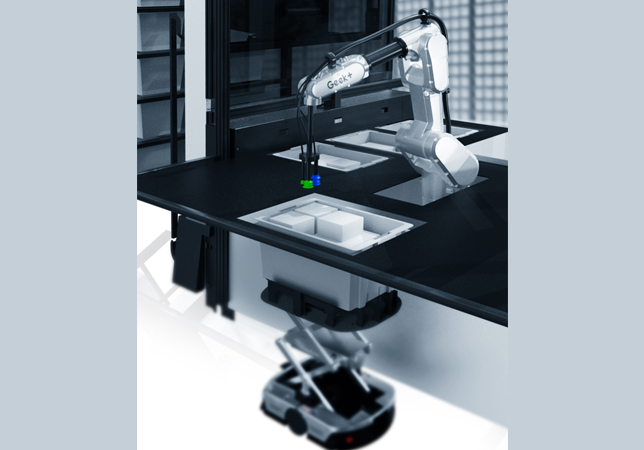

''In order to provide guarantee and accuracy, the company provided new digital and automatic control machines, which are used in all steps of manufacturing such as cutting, punching, roll forming, bending or in stages of part product assembly.

''The painting section consisting of seven steps is another challenge to maintain the guarantee of product quality. These steps begin with chemical treatment for protecting product surface from natural elements and end with painting it by electrostatic powder.

slc's laboratory

''Saudi Lighting has a sophisticated laboratory which tests and researches lighting features with accurate testing instruments. The processes of testing products safety, efficiency, as well as thermal, dust, and water are all completed under hard working conditions in order to achieve the classification conditions requirements of the International Electro-technical Commission 598 and Saudi standards SSA 1318.

services

''Our services start before the sale of our products. These include studies for designing the best solutions and substitutes for lighting. Also our after sales services provide installation consultancy according to our customers' requests and we guarantee our products. Our ultimate goal is to provide products and services that meet our customers' expectations.''

.jpg)

.jpg)

.jpg)