Formwork specialist Peri has developed a formwork solution using special elements based on proven products to realise an architectural and technically sophisticated construction currently being built in Al Ain, UAE.

The Sheikh Zayed Desert Learning Centre resembles a Moebius strip that blends harmoniously into the desert landscape. The structure is characterised externally by its unique design, the particularly high demands placed on the construction work, especially with regard to the formwork and temporary support structures. Ed Züblin Abu Dhabi is the main contractor on the project, which is expected to open by mid-2013.

|

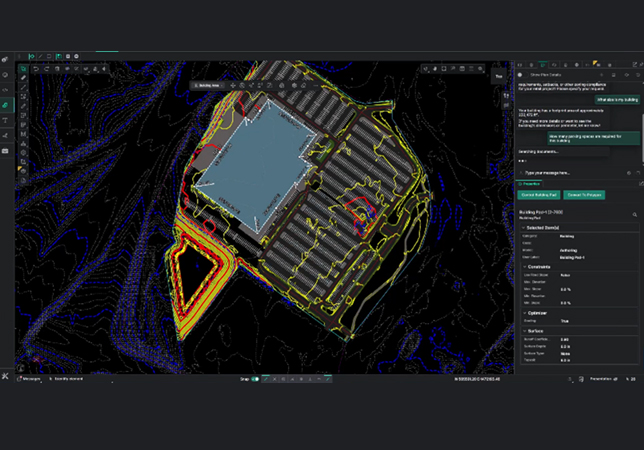

“The constant change in curvature and inclination of the components meant that 3D formwork planning was required, which was the only way to ensure that the structures could be created using the unique formwork units,” says a spokesman for Peri.

When planning the formwork solution, the aim was to accommodate the complex geometry by means of different component dimensions. No inclination, curvature, and arching featured in the components was to be repeated, thus an individual plan of execution was compiled for each wall formwork element. Furthermore, the large component dimensions resulted in high formwork loads during concreting. Among other things, the beams are up to 3 m high and the walls – which carry the loads of large slab areas into a central area – are up to 2 m thick.

The spokesman says these conditions made having a very flexible formwork essential – adaptable to all geometries as well as a fresh concrete pressure of more than 100 kN per sq m.

“Vario GT 24 girder wall formwork was eventually selected whereby the individual system components could be arranged according to the project-specific loads, cross-sections and heights. In order to connect the individual wall formwork elements with each other, despite the numerous inclinations and curvatures, the Peri team of engineers also developed some special steel connection components.”

|

|

Rising steadily from the ground ... the structure is characterised by large diamond-shaped window openings. |

At the desert learning centre, SB brace frames are being used in combination with Vario GT 24 girder wall formwork for wall heights up to 3.6 m and concrete pressures of up to 30 kN per sq m. These brace frames serve as a quick and safe solution for the single-sided transfer of loads and divert the concrete pressure, which occurs during single-face concreting into the substructure.

For the slabs, which have differing thicknesses and ground plans, the Multiflex slab formwork system is being used. Due to the large slab thicknesses, GT 24 lattice girders are used as crossbeams as well as primary beams, which facilitates the creation of large spans with a minimum number of moving parts. “The proven GT 24 girder is characterised by a high flexural rigidity that in turn ensures low deflections,” the spokesman points out.

In areas featuring lower heights, PEP slab props carry the Multiflex formwork. For higher slabs – especially in the roofing and at the top of the elevator shafts – PD 8 shoring towers are being used. These have been typetested for heights of up to 21.3 m and loads up to 62 kN. The supporting units can be preassembled on the ground, if necessary, and then lifted into position by means of a crane.

Teamwork

Peri took on the entire planning of the formwork elements using 3D CAD software. “This was absolutely necessary because there are no two curvatures or inclinations alike in the entire project. Even in the building corners, walls of varying inclinations meet and then merge to form a curvature in the corners themselves,” he points out.

|

The three-dimensional planning and visualisation makes the formwork solution clear and understandable to all those involved and thus creates a sound basis for efficient construction work. In addition, the Peri team produced numerous detailed plans using a scale of 1:5 in order to provide the best-possible support for the assembly of the three-dimensional formwork elements on site.

He adds that design and construction processes also have an impact on the formwork planning: the building twists upwards like a tunnel resulting in the load transfer being centred in only a few places. A large part of the formwork must, therefore, remain in position after being installed until these areas have been completed.

“From the first to the very last of the formwork units, an extremely close eye has to be kept on all formwork and support elements during installation and dismantling – with the immense amount of formwork, and support structures in particular – this presents a major challenge,” the spokesman says.

In addition to the planning and delivery of the system components, Peri also provided reliable logistics and competent on-site support for Ed Zublin Abu Dhabi.

“The constant, close cooperation between Peri engineers and all members of the Ed Zublin Abu Dhabi construction team has guaranteed a streamlined formworking operation. Among other things over the past two years, weekly site meetings have taken place. In spite of the massive proportions of the building, a well-lit structure with large, diamond-shaped window openings and excellent concrete surfaces has been achieved. With their experience and knowhow, Peri design engineers have contributed to the success of this project,” says the spokesman.

|

|

Different systems including the flexible Vario GT 24 girder wall formwork system were used for the Al Ain project. |

The centre is dedicated to Sheikh Zayed bin Sultan Al Nahyan, the late President of the UAE, and is part of the Al Ain Wildlife Park Resort development project, which also includes a wide range of hotels, holiday homes, restaurants and shopping centres.

Upon completion, the centre will offer a unique combination of museums, galleries and natural history exhibitions. “This prestigious project symbolises a change of course by the UAE towards sustainability, and demonstrates that the country attaches great importance to the preservation of both its landscape and culture,” says the spokesman. “Most notable is the focus ensuring strict compliance with environment norms in the construction and operation of the desert learning centre.”

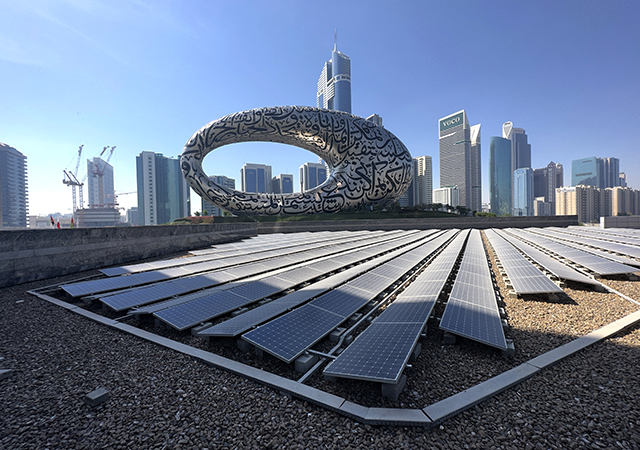

Hence, an innovative building concept, complete with an alternative energy supply and domestic engineering, was developed for the centre.

Among other things, the project is one of the first in the world to utilise large-scale solar cooling. In terms of the power supply, part of the requirements is expected to be covered using photovoltaic systems.

“Energy simulations have shown that total energy needs of the Sheikh Zayed Desert Learning Centre are around 40 per cent less when compared to similar buildings. The aim of all these measures is to secure the Estidama certificate – the Arabian seal of approval for sustainable construction – which guarantees an integrated and environment-friendly method of construction and building operations,” the spokesman concludes.

.jpg)

.jpg)

.jpg)