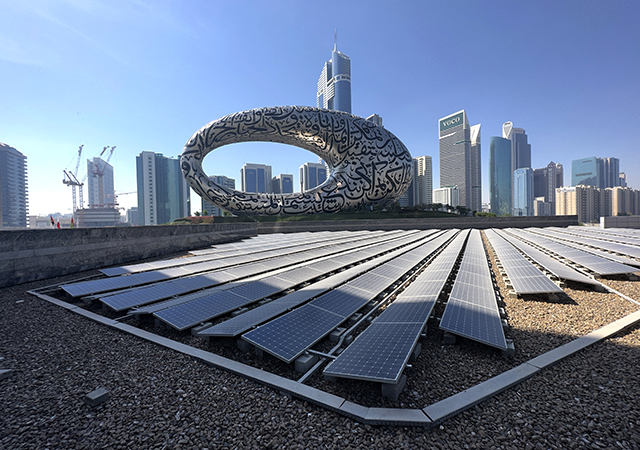

RMD Kwikform is aiding in the construction of three bridges on the $30-billion Reem Island development in Abu Dhabi, UAE, by supplying formwork and falsework solutions.

Designed to improve on-island traffic management, the bridges are set to become an integral part of the city’s transport network, spanning a 20-m-wide canal.

Working alongside main canal contractor Combined Group, and CCECC, a sub-contractor for the bridge project, RMD Kwikform has supplied a solution that was designed using its 80kN Rapidshor support system and utilised both superslim and GTX formwork.

Initially, the Rapidshor system was erected in modules, which were crane handled onto the canal floor. “Each and every one of the Rapidshor legs in the modules had to be individually analysed and stress tested to ensure it was safe for casting,” explains a spokesman for the company, which specialises in providing formwork, falsework, shoring, propping and temporary works solutions.

.jpg) |

The Beirut City Centre project ... a range of RMD Kwikform formwork and shoring equipment used. |

Once the safety and integrity of the Rapidshor modules was ensured, universal steel beams were installed onto the shoring to provide a strong platform to support a further upper tier of Rapidshor that was tested in the same way to cope with the complex nature of the loading on the system, he says.

According to the spokesman, the project has also presented unique challenges, both technically and in terms of timescale, with the 6-m-deep waterway slowly filling with water due to the contractual obligations of the canal’s main contractor.

Work is now due to start on the development of a third bridge structure for which RMD Kwikform has supplied both designs and an equipment solution for completion. This bridge is expected to provide the link into a metro system that will provide an effective public transport system around the island.

Li Guangqi, chief engineer at CCECC, says: “We have been able to take advantage of RMD Kwikform’s extensive range to support the construction of the Reem Island bridges, helping us adapt to the unique on-site conditions. Without RMD Kwikform’s involvement and vital technical expertise, the project may not have been possible and it is a testament to its commitment that we receive ongoing support.”

Werner Wellmanns, sales representative at RMD Kwikform, says: “In working alongside Combined Group and CCECC, we have been able to deliver solutions befitting a development on the scale of Reem Island. Helping to reduce traffic congestion on the island, these bridges will contribute to improving the transport network of both Reem Island and Abu Dhabi as a whole.”

.jpg) |

A 6.5-million-sq-m development costing over $30 billion, Reem Island is the first residential development in Abu Dhabi that allows foreign national ownership. Over 22,000 residential units will be constructed on the island, which lies 600 m off the coast of Abu Dhabi.

RMD Kwikform continues to supply its solutions to a range of projects in the region, right from bridges and tunnels, to dams, and to stadia and towers.

Among other projects, RMD Kwikform is helping Saudi contractor Al Saad General Contracting with the construction of the 125,000-sq-m Beirut City Centre, which will bring the popular City Centre mall chain run by the UAE-based Majid Al Futtaim to the Lebanese capital.

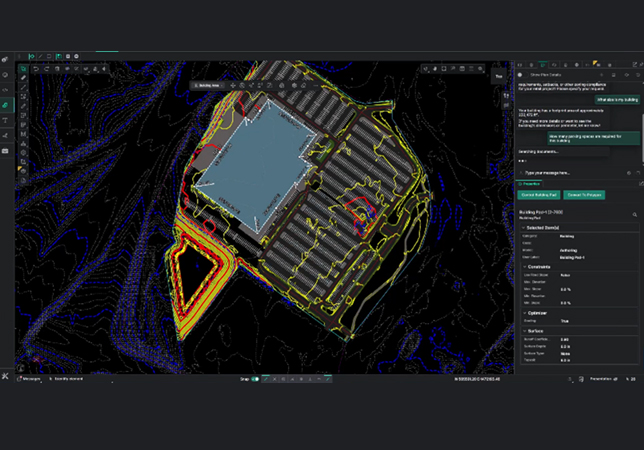

Covering an area of more than 60,000 sq m, the $300-million, six-storey Beirut City Centre will be Lebanon’s largest mall when completed in mid-2013. The construction of this 200-shop development has been fast tracked, thanks in part to the contractor’s use of a range of formwork and shoring equipment from RMD Kwikform.

The project further strengthens RMD Kwikform’s experience in mall construction following significant success in the sector across the Middle East region.

Al Saad General Contracting has purchased more than 300 tonnes of RMD Kwikform’s Kwikstage propping systems, special adjustable bespoke column, straight and curved wall and lift core formwork.

Having proven its equipment capabilities and engineering expertise by being the sole formwork and shoring supplier on the construction of the world’s largest shopping mall, The Dubai Mall, RMD Kwikform was a natural choice for Al Saad, as project manager Nabil Abdallah explains: “Whenever you take on a large landmark project of this kind, there is a great deal of expertise required in its delivery. Having won the project in a highly competitive tender process in early 2009, we ourselves put out a tender for the formwork and shoring requirements for the job and were looking at a sole supplier agreement. In addition to experience, we wanted more than just the obvious criteria of price and availability of off-the-shelf equipment.

“In particular, when we looked at the overall design of the mall, we recognised that there were potential savings to be achieved by opting for an adjustable column formwork solution. We liked RMD Kwikform’s approach in designing a simple system that could be adapted to our site’s exact requirements. To speed up the slab construction, we opted for an in-situ concrete beam system supporting precast deck slabs with an in-situ concrete topping.

“RMD Kwikform’s Kwikstage propping systems provided an economical and quick-to-erect system for the support of the primary beams with the added benefit of being an excellent access system for use during the finishing stages of the works.”

“Youssef Alouf, RMD Kwikform Lebanon branch manager, was on hand on an almost daily basis on the project providing a level of personal support to my construction team, which was invaluable during the early stages of equipment erection and striking,” he adds.

The project is a significant success for the RMD Kwikform operation in Beirut and represents the largest single contract undertaken in the country to date. It came during a record year for the business following previous contract wins on the landmark Mdeirej Bridge redevelopment and a number of medium and large-sized contract wins in the country’s booming commercial development sector.

From humble beginnings in the early 1970s when RMD first started exporting its products to the Middle East, the business has continued to expand its presence, and enhance its service offering across the region. The company says its philosophy is to offer its customers “added value”. It is involved at every stage of the project, consulting with its customers in order to fully understand their requirements, develop tailored design solutions, assist with planning and implementation, and offering dedicated technical site service to support the project. By combining design and engineering expertise, world-leading systems and excellent service levels, RMD Kwikform has become a leader in the formwork and falsework market, says the spokesman.

.jpg)

.jpg)

.jpg)