PASCHAL-Werk G Maier, whose formwork systems have proven themselves in numerous successful projects worldwide, enjoyed a good showing at last month’s Saudi Build exhibition.

The premier construction exhibition in Saudi Arabia, Saudi Build 2013 was held in Riyadh from November 4 to 7.

Paschal was at the exhibition for the fifth time and says it enjoyed a “very good response” with more than 80 serious enquiries for its formwork.

At the event, Paschal showed off its range of products while also highlighting the benefits of its innovative Paschal-Ident software which keeps a track on formwork.

Paschal-Ident is based on modern RFID (radio frequency identification) technology, with RFID chips embedded into formwork elements in order to produce precise inventories of formwork elements.

By using the chips, each individual formwork element receives a globally unique identification (ID) which is then registered, identified and localised, says Jürgen Schnaiter, the managing director of Pascal’s Scientific and Technical Office in Dammam.

Schnaiter continues: “Paschal-Ident not only makes inventory management and planning easier but is also quite useful when financing formwork. Each formwork element, identifiable at any time, provides the ideal security for credit and leasing agreements. With Paschal-Ident, entrepreneurs can use modern formwork elements and save their liquidity at the same time.”

With a production facility for Modular formwork and a stockyard in Bahrain, branches in Abu Dhabi and Dubai in the UAE and sales agents in Iraq and its Scientific and Technical Office in Dammam, Paschal is strongly represented in the Middle East and North Africa (Mena) region.

A new showroom is also set to be opened in Dammam, with work on the project nearly complete.

“Through Pascal’s Dammam office, customers in Saudi Arabia can now benefit from Paschal’s high-class engineering services and quick delivery times,” says Schnaiter.

He continues: “Comprehensive, on-site consulting and services allow Paschal to facilitate successful construction projects across the Middle East from residential, commercial and public buildings to hotels, infrastructure projects as well as water treatment and waste water management facilities.”

Headquartered in Germany, with 50 years of experience and customers in more than 40 countries, Paschal is a sought-after partner for concrete projects worldwide. Its range of services includes the development and production of formwork and shoring systems, global distribution, consulting and additional construction services.

Paschal manages four branch offices and a service centre in Germany from its main office in the city of Steinach in southern Germany, in addition to having numerous subsidiaries and international partnerships. Today, the Paschal Group is among the 10 largest providers of quality products for concrete construction in the world and cooperates with numerous trading partners.

Paschal’s main products, known throughout the world, are technically advanced, cost-effective solutions to meet formwork demands in modern concrete construction. Its products are known for their innovation and efficiency, as well as quality and durability.

The company’s range of products includes the technically advanced and market-leading circular trapezoidal girder formwork TTR and TTS, with wooden or steel facing, and the Modular universal formwork in numerous dimensions with matching large-size elements and Logo.3 formwork. Additional product highlights include round and rectangular column formwork, products for climbing and single-sided forming, as well as support systems for precast or in-situ concrete slabs.

Most of these products were showcased by Paschal at Saudi Build.

Recent product developments at the company include TTK, new Logo.3 element sizes along with the formwork software PPL 10.0 with 3-D features. In the area of specialised formwork, Paschal implements customised formwork elements in steel for non-standardised requirements such as shaft formwork, exceptional column cross-sections, tunnels and vaults.

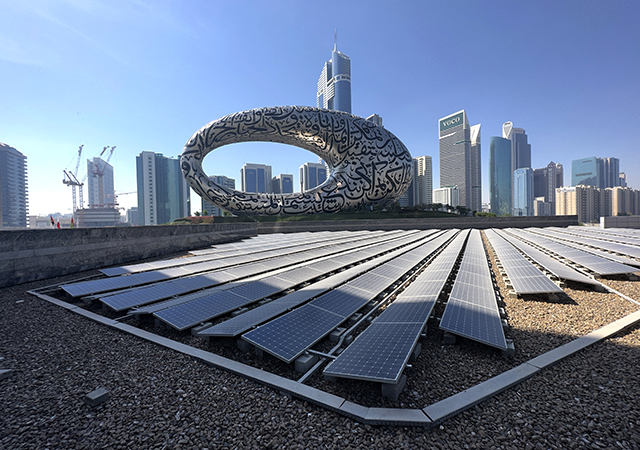

Madinah STP

Among the striking projects in the region where Paschal’s Logo.3 wall formwork is being used is Saudi Arabia’s largest sewage treatment plant (STP) in Madinah, which is being constructed by Riyadh-based contractor System Technology Company (SysTech).

Costing SR300 million ($80 million), the STP is designed to cater for one million people and treats waste water in three stages to provide water for agricultural irrigation.

“The new structures are built in three construction phases. Each will include two large activated sludge basins (98.5 by 56.7 m), equipped with six flow inversions over a span of 9 m, which move the water volume. Large round basins (outer diameter: 39.9 m), small round basins (outer diameter: 33.6 m) and several conventional technical infrastructure buildings will be built adjacent to these,” says a spokesman for Paschal.

In order to attain the formwork height of 9.05 m, two elements with a height of 3.40 m (at a width of 2.40 m) were installed, and two elements with a height of 2.40 m, but widths of 1.35 m and 0.90 m, were stacked on top of these in a sideways orientation.

“Set-up, assembly and implementation proved to be surprisingly straightforward, with the concrete face of equally high-grade. Using these methods, the approximately 520 m of linear wall were completed to the customer’s full satisfaction,” concludes the spokesman.

Work on the project started in June 2012 and is scheduled to be commissioned in August next year.

.jpg)

.jpg)

.jpg)